Nonlinear Material Modeling

Nonlinear Material Modeling - Nitinol - Nickel-Titanium Alloy

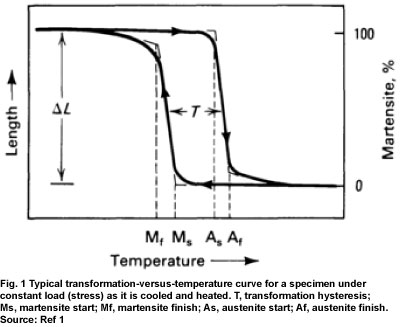

One special example of nonlinear material modeling involves what is known as Superelastic or Shape Memory materials. There are sevearl materials that exhibit these characteristics including multiple metal alloys as well as some plastics. In the Super Elastic condition the metal behaves very much like a rubber while in the Shape Memory mode the application of heat will cause the material to go back to it's original condition. Nitinol can be taylored to behave in various ways heat treatment and mechanical work. Control of mechanical properties is through the manipulation of transformation properties: Ms, Mf, As, Af. Ms and Mf are the Martensite start and finish temperatures while As and Af are the Austenite start and finish temperatures. A typical transforation-versus-temperature curve is shown in Fig. 1 below. (Ref ASM)

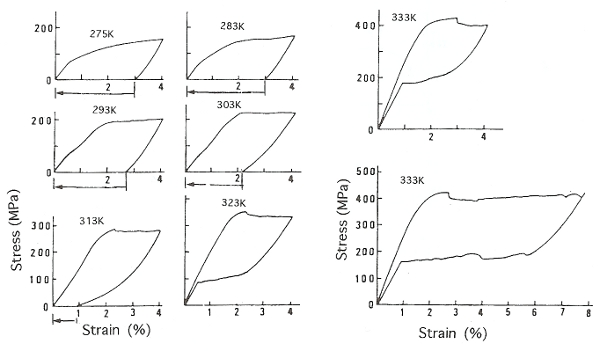

These properties are controlled to develop a wide range of responses for Superelastic and Shape Memory materials such as Nitinol. Fig. 2 below demonstrates some Stress-Strain properties that are achieved through these methods.

Fig. 2 Three NiTi shape Memory Alloys, Stress Vs. Strain Curves at different temperatures. Materials were annealed at 313K with 25% cold rolling. (Ref: Shape Memory Materials; K. Otsuka; C.M. Wayman)

The finite element analysis (FEA) simulation shown in the movie below demonstrates a device made of Nitinol (Nickel-Titanium alloy) modeled in the Super Elastic condition. Severe twisting of the component is required to insert it. Upon release the component holds it's position without plastic deformation. Many complex behaviors can be developed through the use of advanced materials such as Nitinol.